MASS-CUSTOMISED BIKE SADDLES

atum3D is dedicated to bringing the benefits of additive manufacturing to the world of sports. Together with BASF

Forward AM, we are proud to present the first integral solution to manufacture individualised bike saddles on a

mass-production scale. Bridging the gap between end-user quality requirements, process performance, and costefficiency,

our DLP Station enables on-site saddle printing. The result? Fast and accurate production of exceptionally

comfortable individualised, robust bike saddles that allow cyclists to maximise both experience and performance.

1. PRESSURE MAPPING

Pressure Sensitive Foil

Using a printed flexible pressure-sensitive foil, the first step is to

scan the individual cyclist’s bone structure. This process results

in a pressure map, indicating the precise mass and pressure

distribution applied to the saddle by the cyclist.

2. MODEL

Hyperganic 3D Modelling Software

Specialised software translates the pressure map into a bespoke

lattice design of the multiple functional zones within the saddle,

finetuning each one to the cyclist’s individual physical properties.

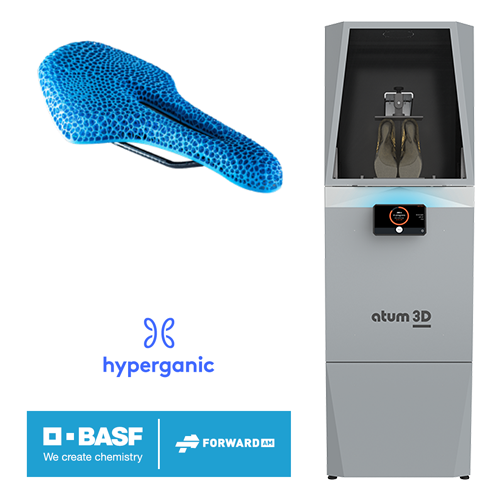

3. PRINT

Operator Station Professional

After importing the design in atum3D Operator Station, our

software prepares the bike saddle model for print in just a few

clicks. Multiple saddles can be combined in a single printer run.

DLP Station 5-365 EXZ

The extended Z-axis allows printing personalised saddles up to

45 cm in length with accuracy and speed. This enables new levels

of cost-efficiency for customised, industrial-scale manufacturing.

BASF Forward AM Ultracur3D® EL 150 resin

Ultracur3D® EL 150 by BASF Forward AM is ideally suited for

applications requiring elasticity and flexibility, delivering medium

hardness and an optimal combination of high strength, excellent

elongation at break and outstanding long-term rebound.

4. POST-PROCESSING

Cleaning & Post-Curing

After printing, the cleaning and post-curing processes can be

largely automated to further reduce the lead time and increase

ease-of-use. To this end, atum3D offers the Cleaning Station,

Curing Station and Finishing toolkit extensions.

BASF Forward AM Ultracur3D® Coat F Coating

In the final step, the production saddle is given a hard-wearing

yet flexible coating of BASF Forward AM Ultracur3D® Coat F,

available in an extensive spectrum of colors. With class-leading

adhesion and outstanding elasticity, this makes the perfect

finishing touch for lattice-structure applications that need to

combine excellent flexibility with durability and attractive haptics.

5. RIDE

The comfort of a personalised, high-quality saddle

The saddle is one of the crucial contact points between cyclist

and bike. A well-fitting saddle is vitally important to every cyclist,

decisive to both performance and comfort. Finding the perfectly

fitting saddle was a challenge - until now!

PERSONALISED BIKE SADDLE BENEFITS

The saddle’s internal lattice structure is composed of thousands of

individual 3D printed struts, each designed to dissipate the high

pressure applied by the rider when cycling. Leveraging the benefits

of the lattice structure, this new saddle is a massive improvement in

cushioning and pressure distribution, delivering unprecedented comfort

for casual cyclists and a performance leap for ambitious riders.

Summarised, the benefits of the atum3D products in this integral

personalised bike saddle serial production solution include:

- Best-in-class build speeds of up to 150 mm/hour.

- Intuitive print job preparation, easy printer set-up and workflow.

- DLP Station 5-365 EXZ’s extended Z-axis allows printing multiple

personalised saddles up to 45 cm in length in a single run. This

large build envelope enables new levels of cost effectiveness for

uniquely customised, industrial-scale manufacturing.

- Print robust bike saddles with a perfectly individualised saddle

structure that optimally distributes bone and muscle pressure,

maximizing rider comfort by minimizing peak-pressure points.

- With this integral solution, you are ready for mass customization

and on-site printing.