Curing Station offers the best of all three key post-curing factors: UV light, heat and oxygen. The key practical benefits are twofold: speed and accuracy. Without the curing-inhibiting oxygen present, the resin post-curing process is significantly accelerated. Radiated heat increases the mobility of the polymer resin, further increasing speed and completeness of the post-curing reaction.

High intensity UV light combined with heat in a vacuum environment allows Curing Station to post-cure printed parts more thoroughly than other post-curing solutions. All three key variables can be independently controlled by the user in a single automated curing preset, which makes Curing Station an exceptionally versatile device.

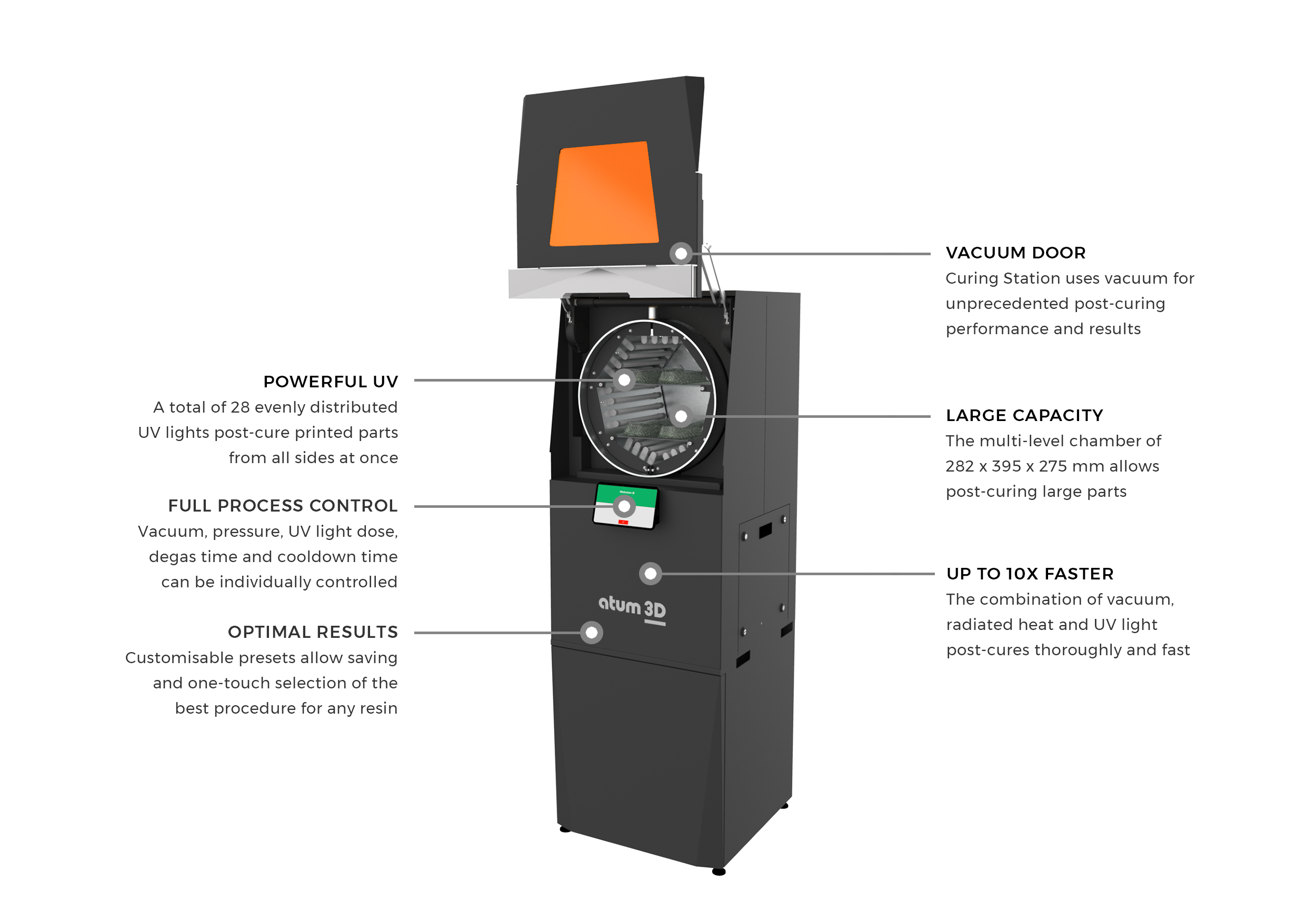

Curing Station produces a total radiated power of 45 Watts broad-spectrum UV light. The 28 UV lights are evenly distributed in 360 degrees around the parts, which creates an even exposure from all sides. The powerful lights also have a radiated heat curing effect on the parts inside the chamber. The absence of oxygen creates a more complete reaction than at atmospheric pressure.

The touch screen interface allows the user to fully customise automated curing presets. The vacuum, pressure, UV light dose, degas time and the cooldown time can be individually controlled in each process step. By combining a series of subsequent steps in a preset, Curing Station allows creating any conceivable curing process based on the resin properties and application requirements.

With its capacity of 282 x 395 x 275 mm, Curing Station makes it possible to post-cure even the larger parts. The easily removable borosilicate plates allow selecting the optimal setup for the job. Are you looking to post-cure many smaller parts in a single run, using the multi-level setting, or several larger objects by removing the top plate and utilizing the full internal height?

Post-curing plays an important role in any integral 3D printing application solution. Now it’s possible to conveniently create print jobs with Operator Station software, swiftly and accurately print parts in any resin using DLP Station, thoroughly clean the results in one of our Cleaning Stations and post-cure parts to their final specification in our state-of-the-art Curing Station.